Structural Steel

Structural Steel Fabrication & Erection

With specialized skills in structural steel design, fabrication, and erection, Ogletree’s caters to the varied and unique requirements of wineries, commercial ventures, and large or custom residential projects. The Ogletree’s team ensures efficient execution and top-tier quality, delivering reliable fabrication solutions to our valued clients.

Ogletree’s Quality Assurance program is in compliance with AWS, AISC and ASTM F1193, ensuring a quality product every time.

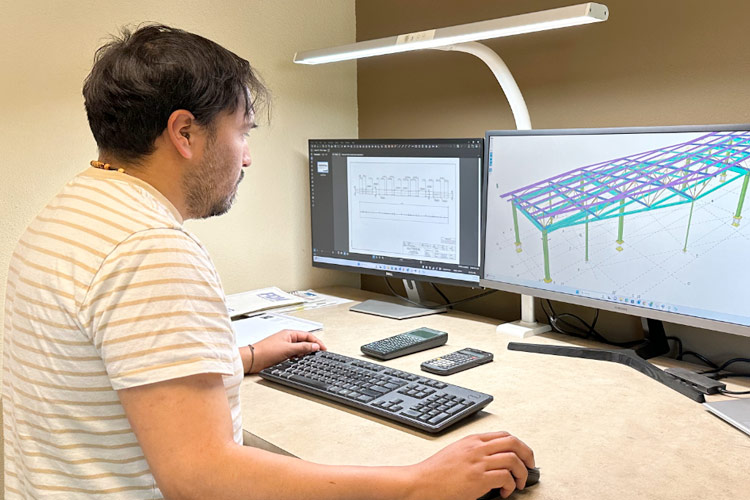

Structural Steel BIM Modeling & 3D Scanning

Ogletree’s utilizes BIM modeling to produce fabrication drawings for all of our projects. We use Tekla, our BIM software, to model the structural steel projects that we will eventually fabricate upon approval.

The 3D modeling process provides an interactive three dimensional model with precise detail of every aspect of our client’s project, allowing seamless coordination with other trades. If a project integrates with existing work, Ogletree’s can scan the existing conditions using the latest technology in LiDAR scanning to transform the existing conditions into an as-built 3D BIM model.

Structural Steel Fabrication

We produce quality steel, stainless steel, or aluminum parts with clean, precise welds, ensuring that the components we deliver fit up accurately during installation. Our attention to detail allows us to deliver structural steel components efficiently, resulting in high-quality structural steel fabrication that meets the requirements of the project.

Structural Steel Erection

Our structural steel erection capabilities ensure proper installation for a variety of projects. We efficiently handle the assembly and placement of structural steel components for commercial buildings, custom homes, and wineries.

Contact Us

Ogletree’s looks forward to being your trusted partner in structural steel projects. Contact us today to learn more about what we can do to bring your next project to a higher level.